RE PIETRO SRL designs and delivers complete productions lines, from the processing machines to the packaging line, and offers an efficient after-sale service.

Popping Machine RP-EVO

Popped chips, popped snacks, healthy snacks, non-fried snacks, non-fried chips: call them what you want but one solution POPPING MACHINE RP-EVO.

With the NEW Popping Machine RP-EVO, the production of puffed cereal cakes or NO-fried snacks with the same machine becomes reality!

Choose the shape, assemble the appropriate mould, select the proper PLC program (for cakes or snacks) and that’s all. Because no Popping Machine is as flexible as the new RP-EVO.

Snacks and puffed cakes with one machine

The market demands healthy and low-fat products and the new RP-EVO, flexibly, responds.

Create your favorite recipe and let yourself be surprised: rice, corn, cereals, legumes and micropellets, combined in original and tasty mixes, become light and airy puffed cakes ideal for breakfast or as bread substitutes, but also crunchy and healthy popped snacks, of any shape and thickness. And all this is possible without changing machine. Because no Popping Machine is as flexible and easy to use as the new RP-EVO.

Technical features

■ Solid frame, made of chemical nickel coated carbon steel (not painted).

■ Hydro-mechanical pressing system to guarantee the maximum pressure with the minimum power consumption.

■ Volumetric dosing system for the raw materials, pneumatically activated.

■ Hardened steel molds coated with titanium nitride to guarantee a long lasting life and to avoid the sticking of the raw materials.

■ The molds are heated by high density cartridge heaters.

■ Separate temperature control of the molds (upper and lower).

■ PLC Siemens S7-1200 + capacitive HMI Weintek 7″ WVA.

■ Remote control is possible through Internet.

■ Licence OPC-UA Server for Industry 4.0.

■ MOCA compliance.

■ CE compliance.

Available models

Choose the shape of your snack.

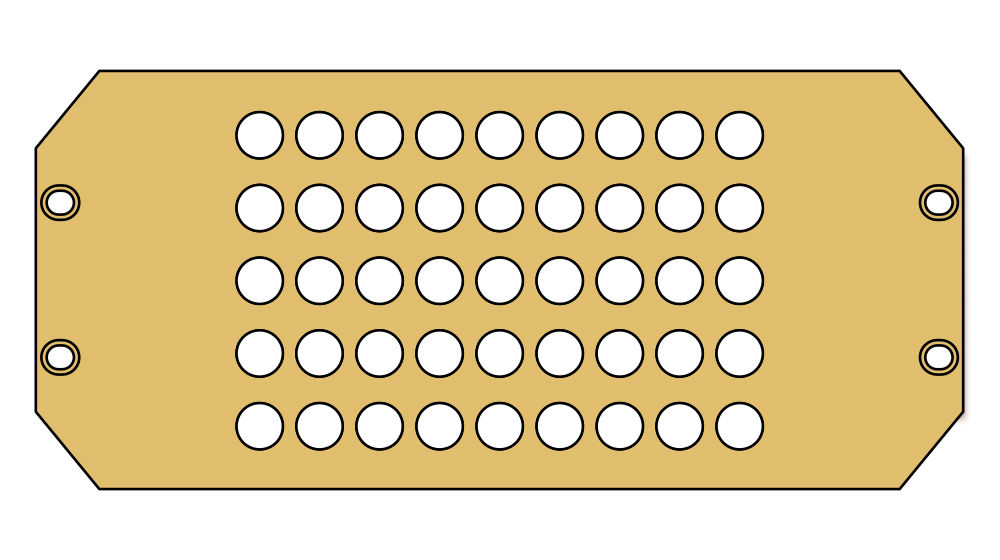

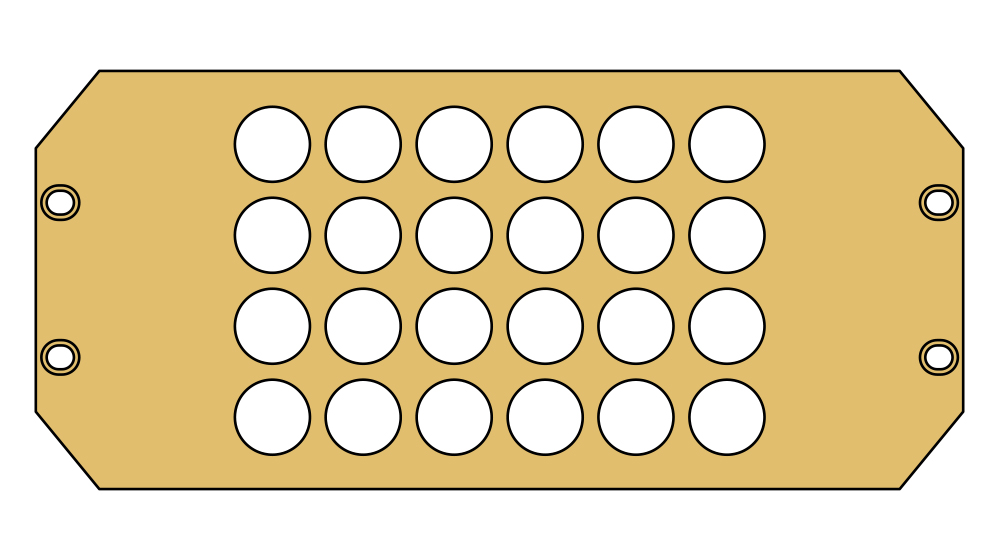

45/25C

Shape: Round Ø 25 mm

Pcs/cycle: 45

Capacity*: Up to 16.200 pcs/h

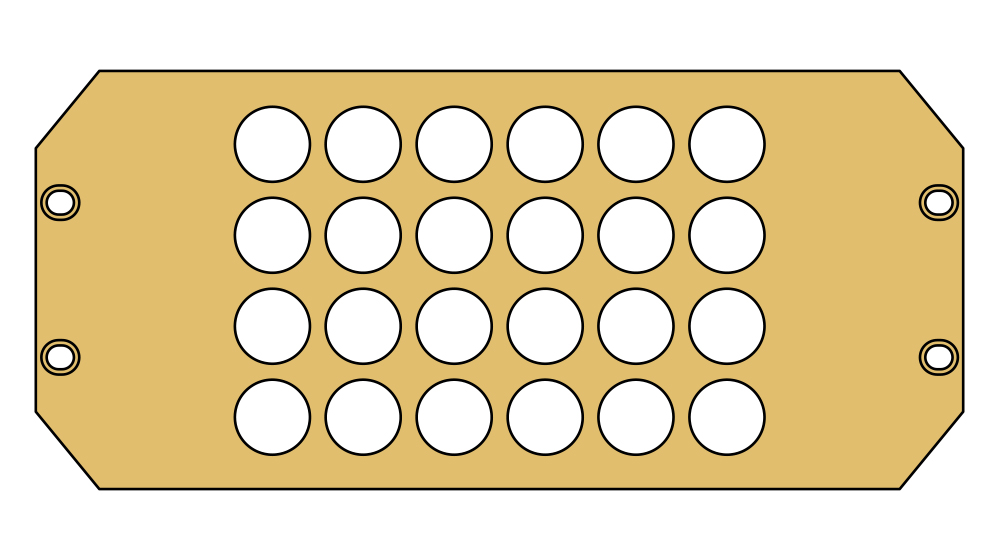

28/35C

Shape: Round Ø 35 mm

Pcs/cycle: 28

Capacity*: Up to 10.080 pcs/h

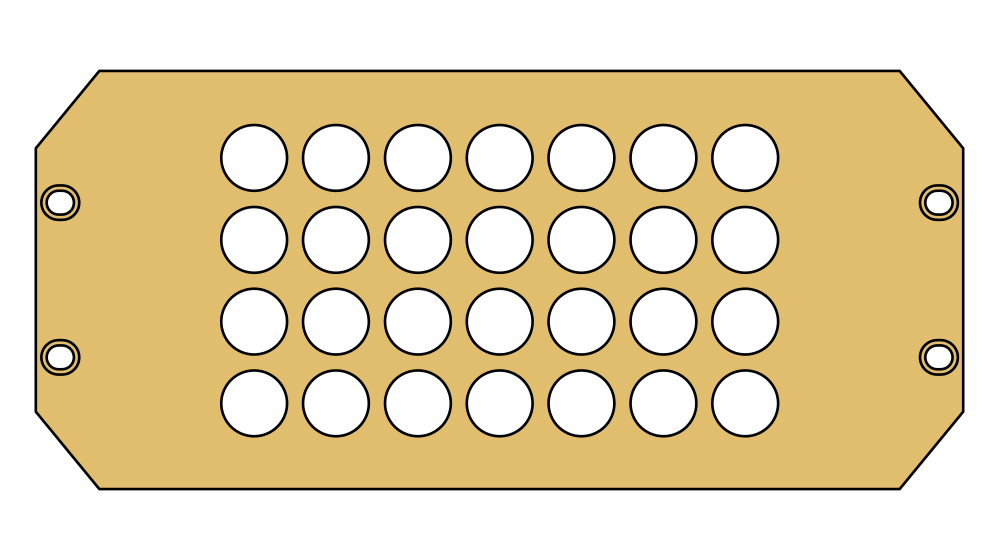

24/40C

Shape: Round Ø 40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

24/45C

Shape: Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

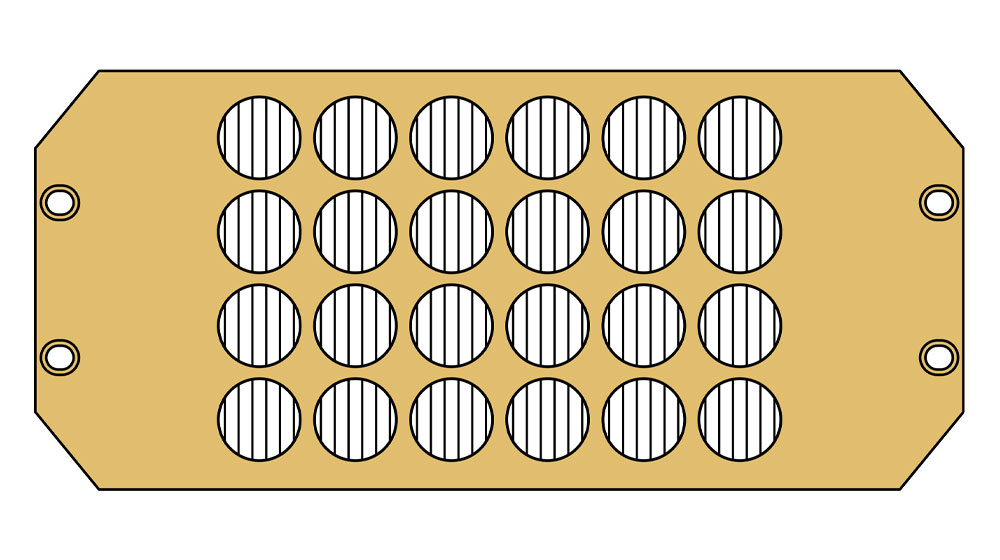

24/45CR

Shape: ridge Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

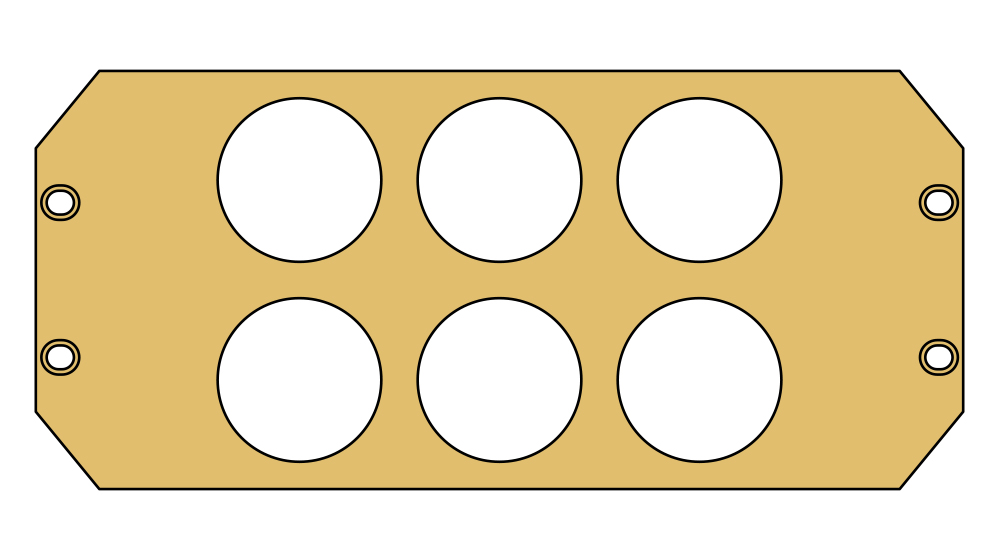

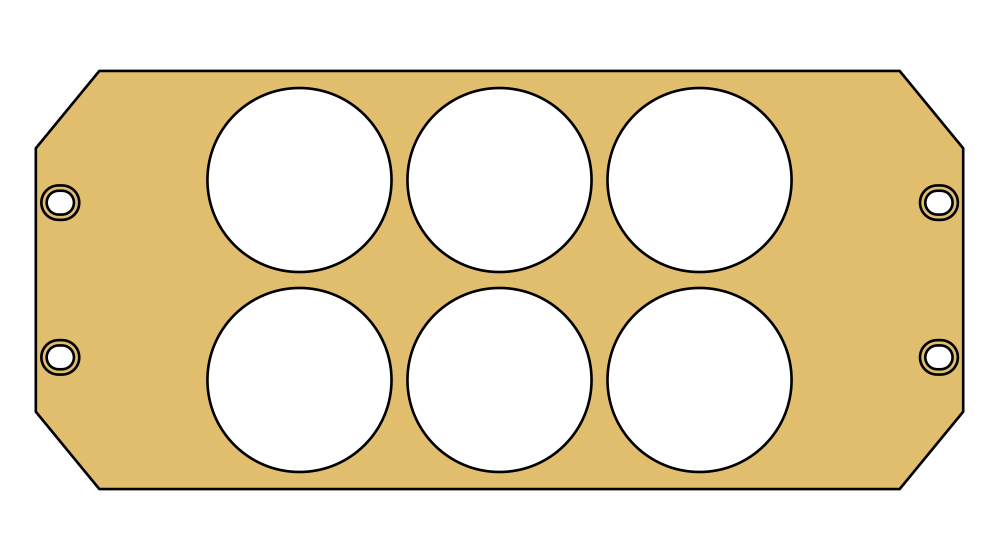

6/90C

Shape: Round Ø 90 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

6/100C

Shape: Round Ø 100 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

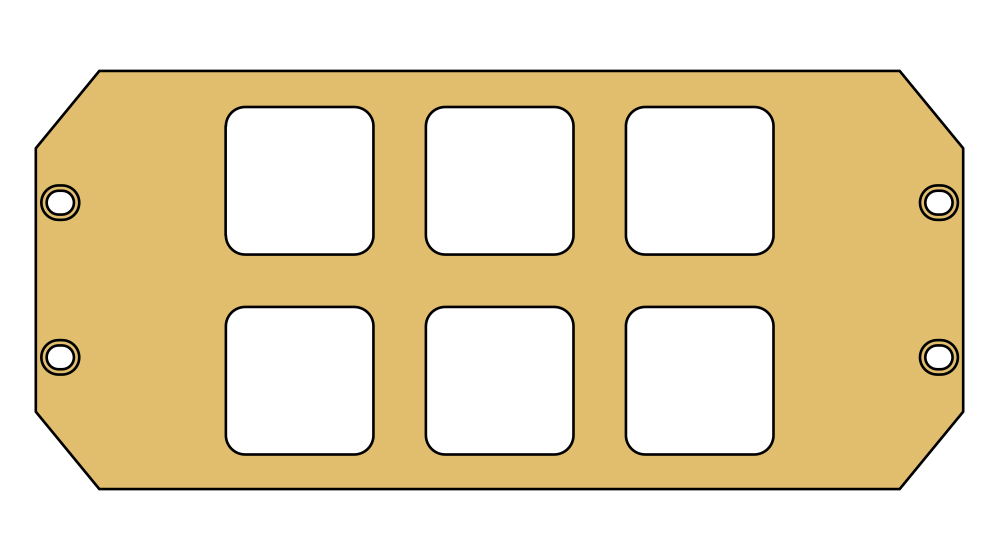

6/Q

Shape: Square 80×80 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

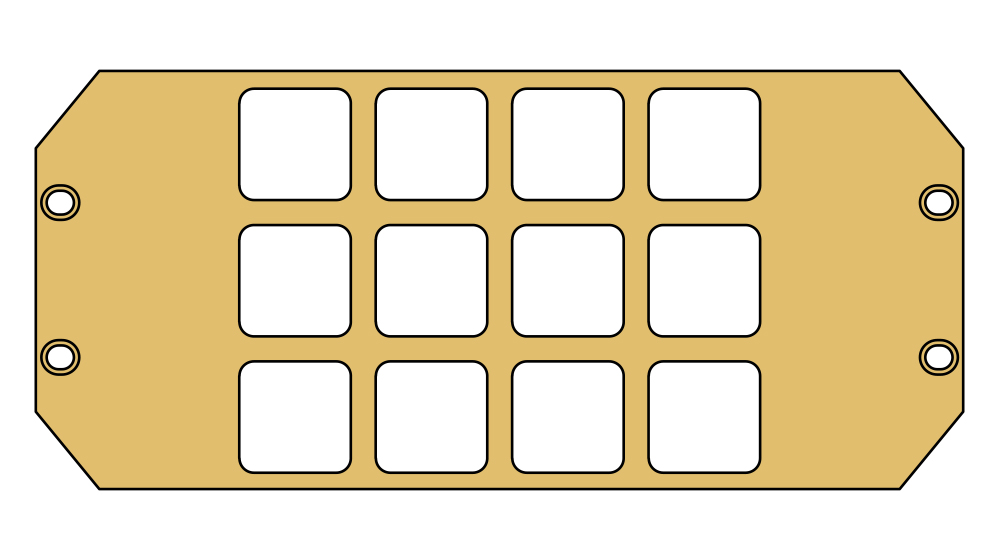

12/Q

Shape: Square 60×60 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

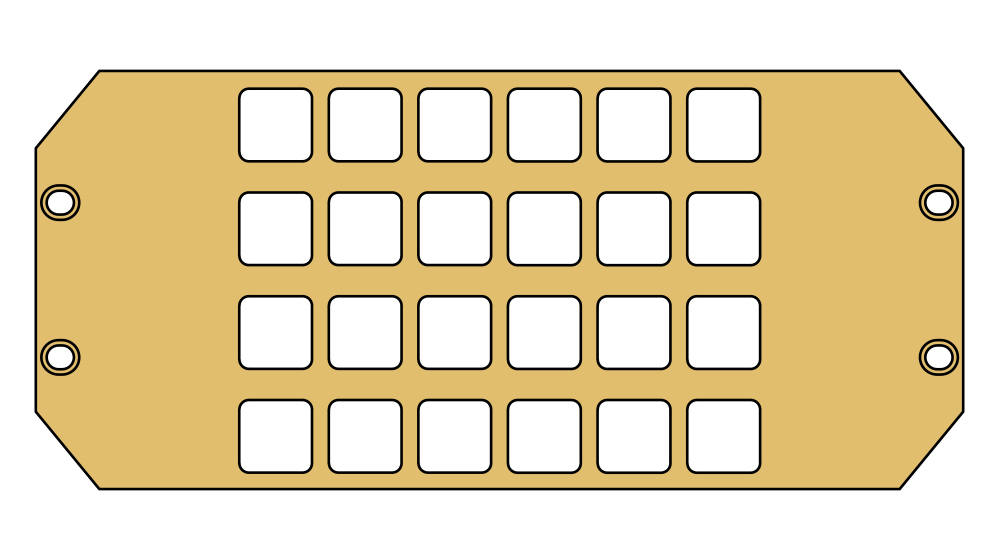

24/Q

Shape: Square 40×40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

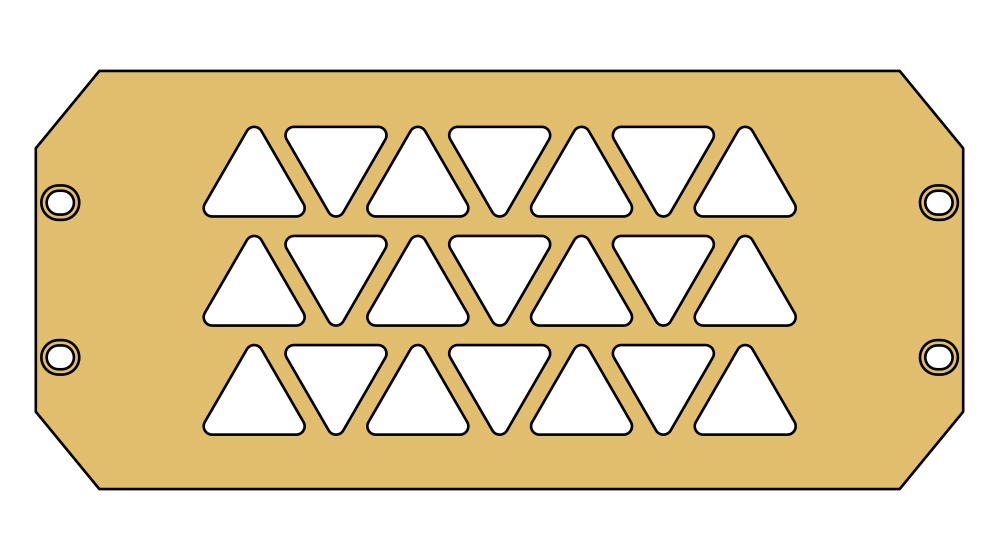

21/T

Shape: Triangular 56 mm per side

Pcs/cycle: 21

Capacity*: Up to 7.560 pcs/h

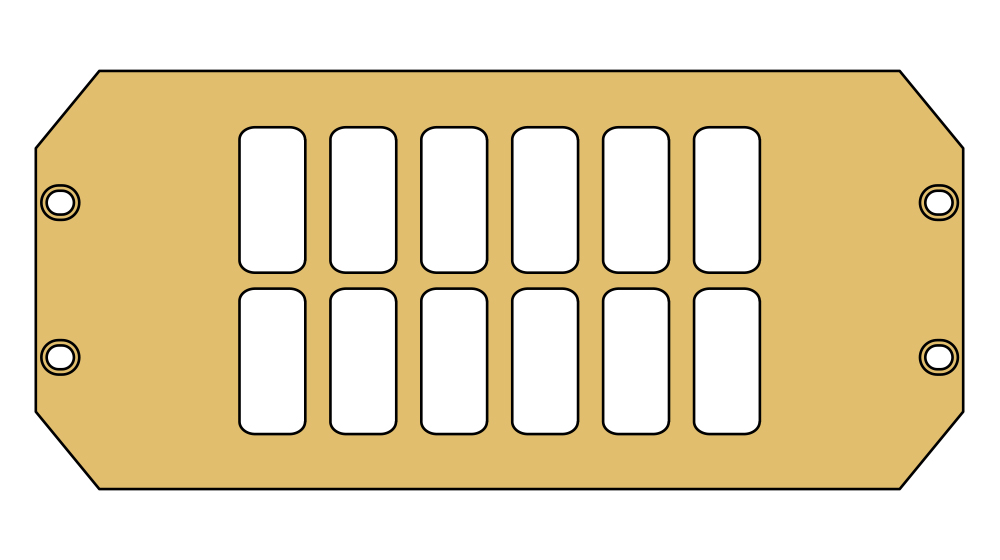

12/R

Shape: Rectangular 80 x 35 or 100 x 35 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

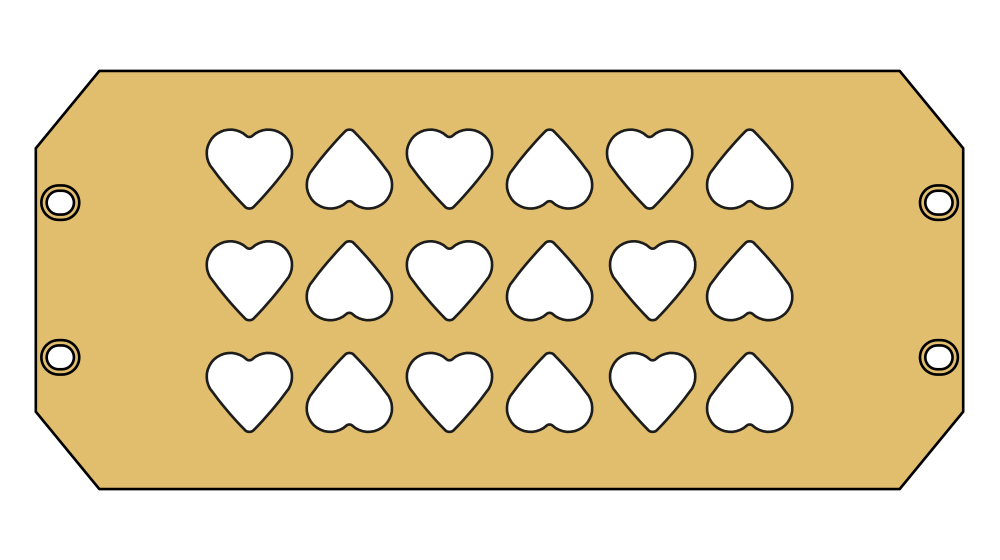

18/HR

Shape: Heart

Pcs/cycle: 18

Capacity*: Up to 6.480 pcs/h

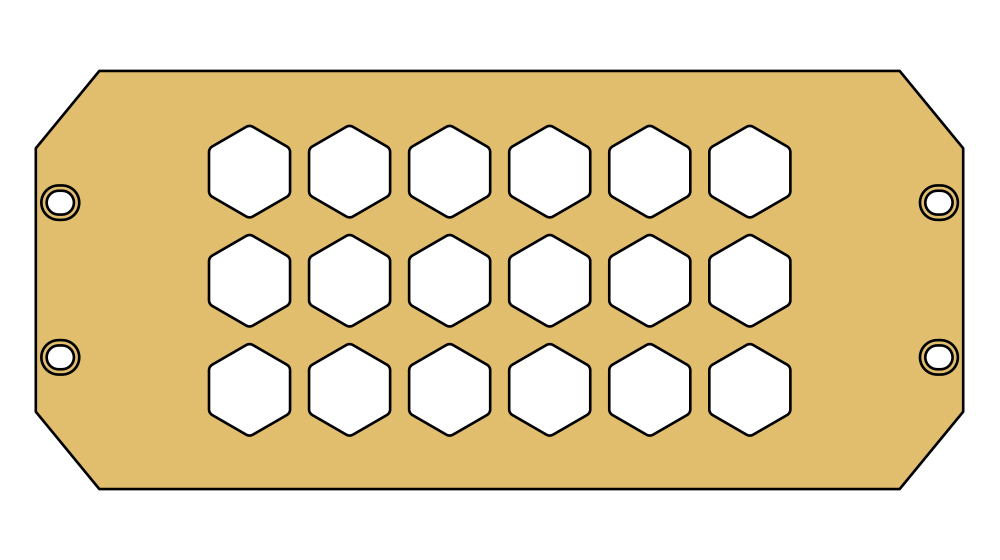

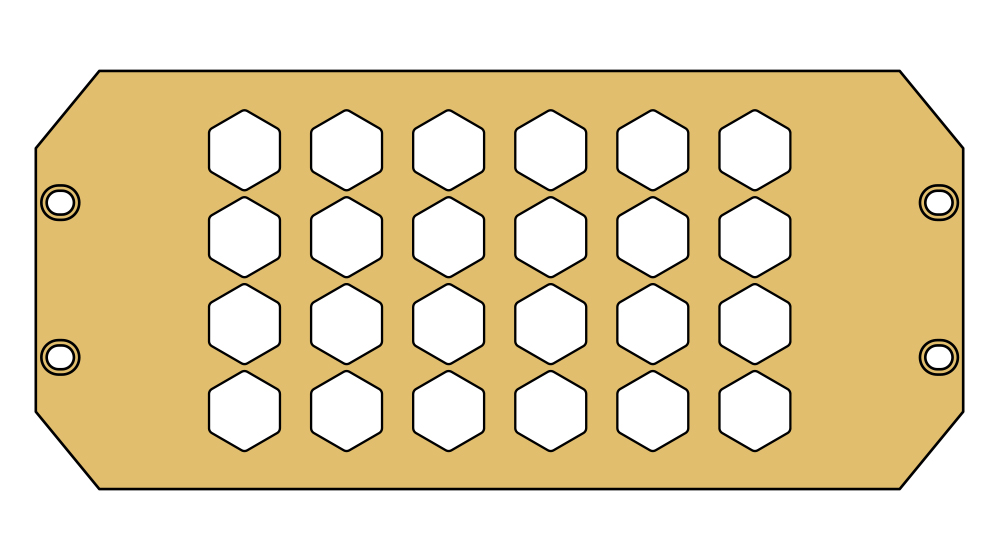

24/45HE

Shape: Hexagonal Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h