RE PIETRO SRL designs and delivers complete productions lines, from the processing machines to the packaging line, and offers an efficient after-sale service.

Popping Machine RP-EVO: the next-generation press for rice cakes and non-fried snacks

Popped chips, popped snacks, healthy snacks, non-fried snacks, non-fried chips: call them what you want but one solution POPPING MACHINE RP-EVO.

The RP-EVO Popping Machine by Re Pietro represents the evolution of technology for the production of rice cakes and non-fried snacks. Designed to deliver high industrial performance, it combines mechanical precision, digital control, and production flexibility, offering a complete solution for those who want to create healthy, crunchy, low-fat products.

This rice cake machine ensures uniform results with consistent quality and is the ideal choice for companies looking to expand their product range with wholesome, on-trend snacks, responding to growing market demand for healthy, non-fried foods.

With the new RP-EVO series Popping Machine, producing cereal cakes or non-fried snacks with a single machine is finally a reality. You choose the format, install the appropriate mould, select the PLC program (cakes or snacks), and you’re ready to go. Because no Popping Machine is as flexible as the new RP-EVO.

Advanced pressing technology for cakes and snacks

At the heart of the RP-EVO is its pressing system, capable of transforming kernels of corn, rice, spelt or other cereals into light, fragrant cakes. Thanks to electronic management of temperature, pressure, and cooking time, the machine ensures maximum precision and process repeatability, with optimized production cycles that reduce waste and downtime.

The true innovation lies in the ability to create both cakes and snacks with a single machine, in complete freedom: rice, corn, mixed cereals, legumes, and micro-pellets can be combined to create original and tasty blends, ideal for breakfast or as bread substitutes, as well as for crunchy, healthy snacks of any shape or thickness.

The RP-EVO is designed and built with high-quality materials and is a 100% Made in Italy product, synonymous with reliability and mechanical innovation.

Efficiency, versatility, and customization for every production need

The RP-EVO Popping Machine can be customized with different shapes, diameters, and thicknesses according to production requirements. It can be configured to produce round cakes, square cakes, or other shapes, flexibly adapting to market demands.

Operational safety and compatibility with automation systems make the RP-EVO an ideal machine even for high-capacity production lines.

With the RP-EVO Popping Machine, Re Pietro reinforces its expertise in industrial machines for rice cakes and popped snacks, offering the perfect combination of Italian mechanical tradition and cutting-edge technology. A solution designed for those who want to invest in quality, efficiency, and innovation, transforming simple cereals into high-value products with maximum creative and production freedom.

For small-scale production, also discover the MRC Popping Machine — simple and compact, ideal for small bakeries, farms looking to add value to their cereal crops, and R&D laboratories within large snack-manufacturing companies.

Technical features

■ Solid frame, made of chemical nickel coated carbon steel (not painted).

■ Hydro-mechanical pressing system to guarantee the maximum pressure with the minimum power consumption.

■ Volumetric dosing system for the raw materials, pneumatically activated.

■ Hardened steel molds coated with titanium nitride to guarantee a long lasting life and to avoid the sticking of the raw materials.

■ The molds are heated by high density cartridge heaters.

■ Separate temperature control of the molds (upper and lower).

■ PLC Siemens S7-1200 + capacitive HMI Weintek 7″ WVA.

■ Remote control is possible through Internet.

■ Licence OPC-UA Server for Industry 4.0.

■ MOCA compliance.

■ CE compliance.

Available models

Choose the shape of your snack.

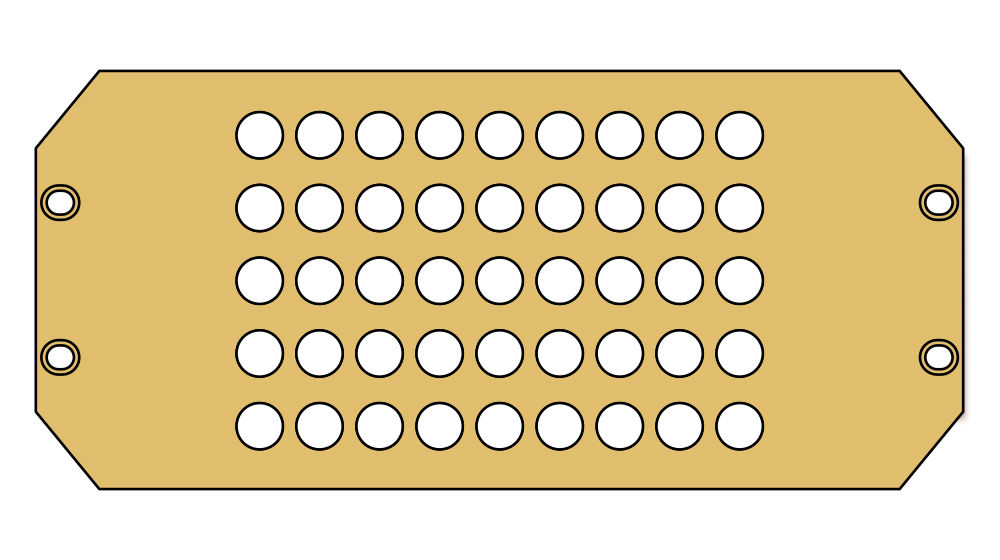

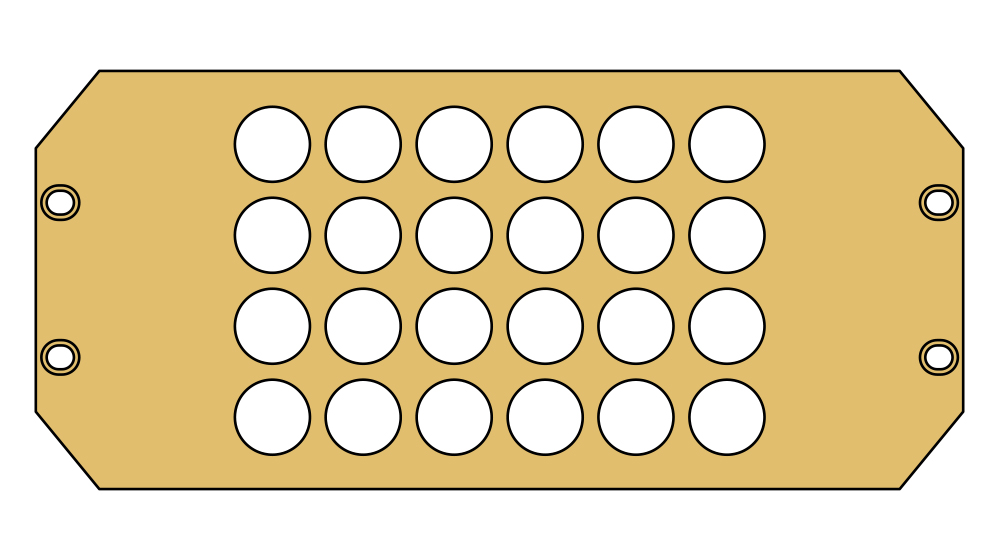

45/25C

Shape: Round Ø 25 mm

Pcs/cycle: 45

Capacity*: Up to 16.200 pcs/h

28/35C

Shape: Round Ø 35 mm

Pcs/cycle: 28

Capacity*: Up to 10.080 pcs/h

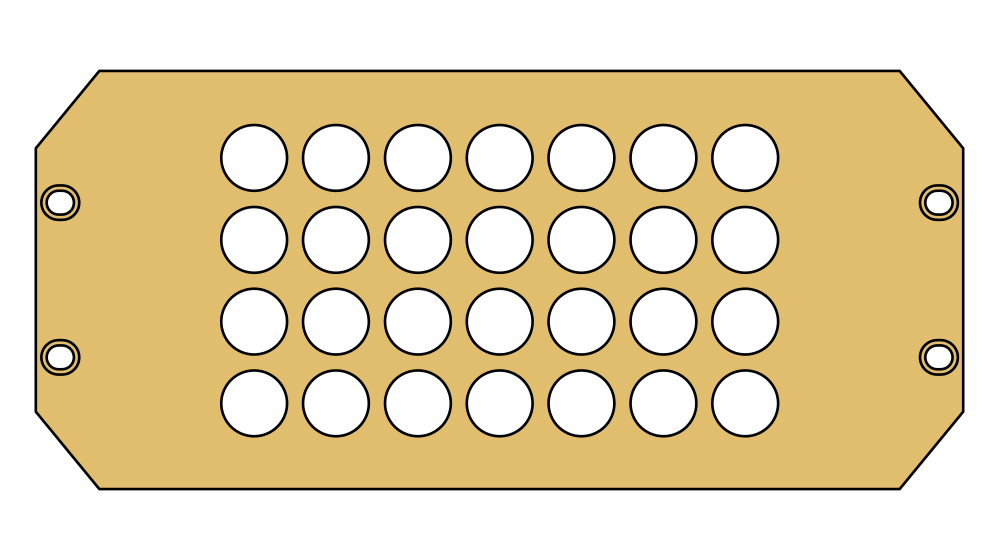

24/40C

Shape: Round Ø 40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

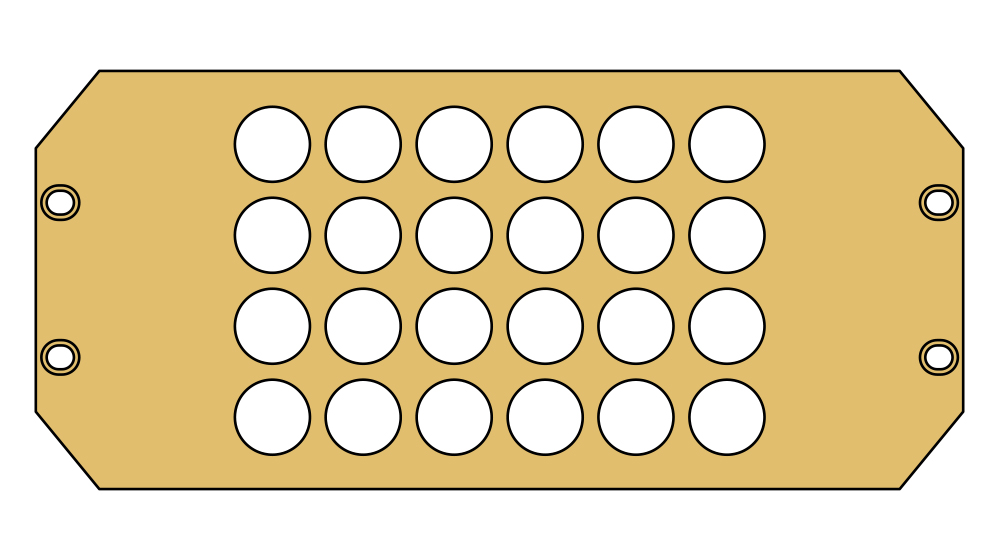

24/45C

Shape: Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

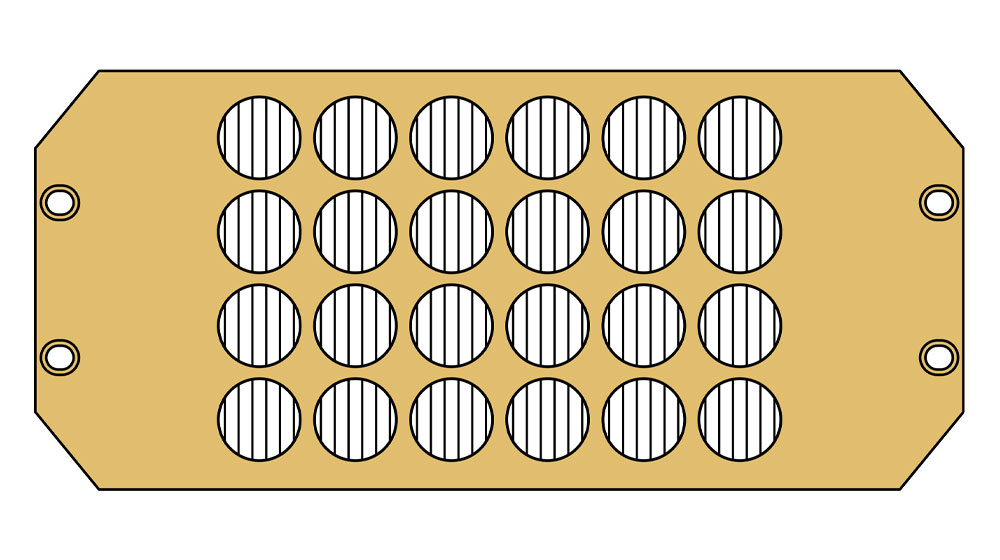

24/45CR

Shape: ridge Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

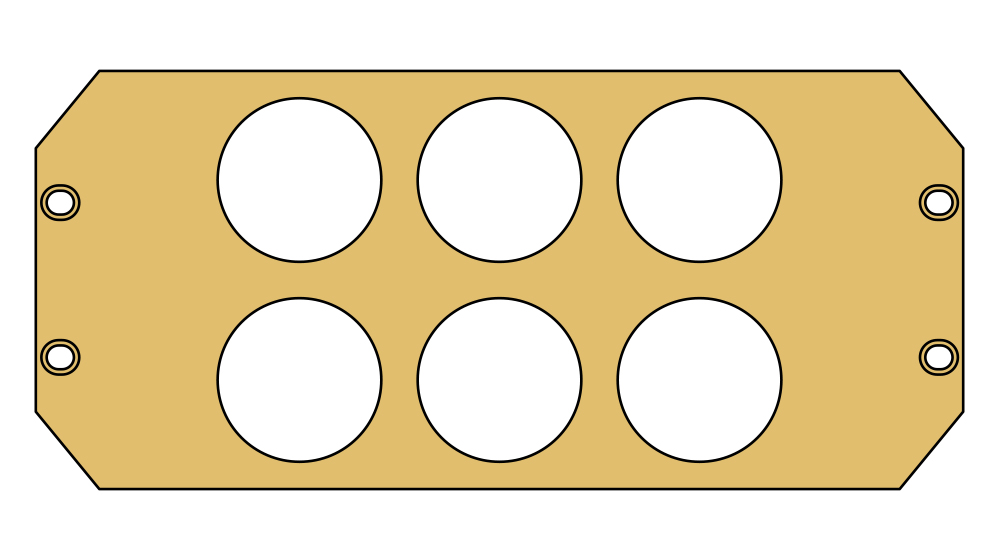

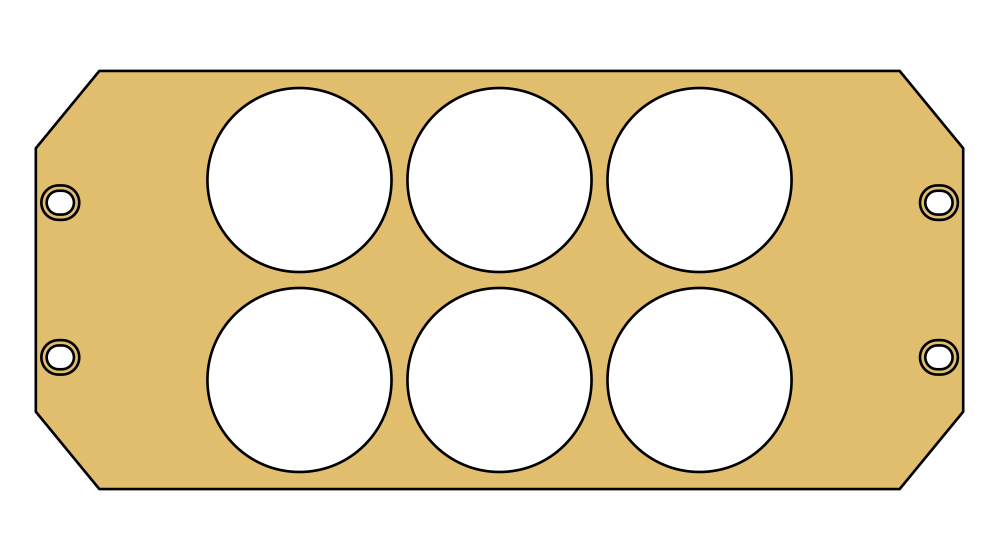

6/90C

Shape: Round Ø 90 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

6/100C

Shape: Round Ø 100 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

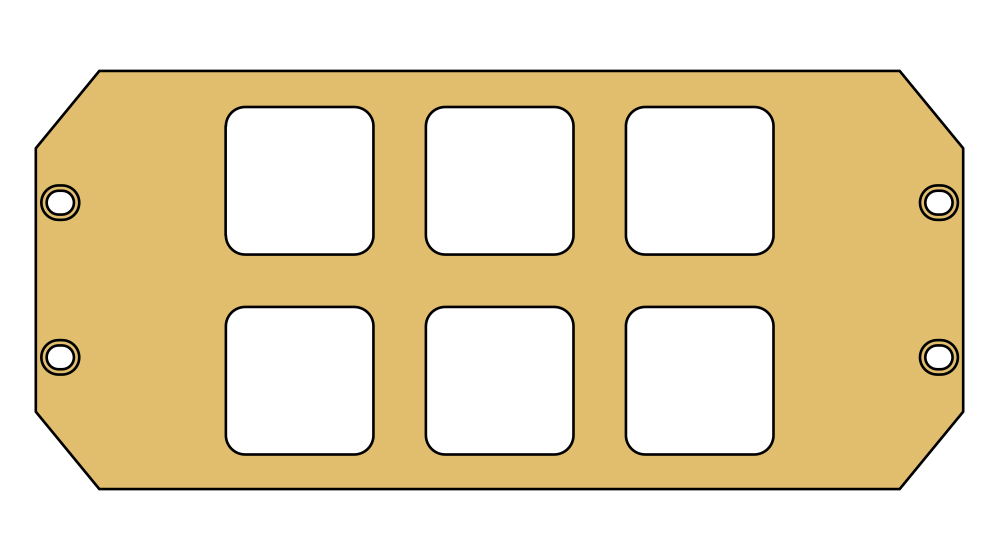

6/Q

Shape: Square 80×80 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

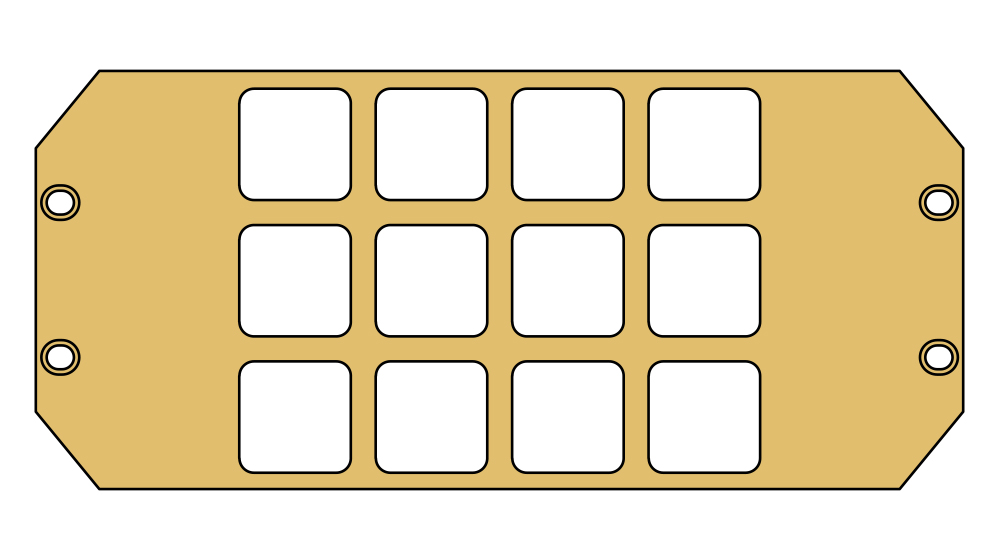

12/Q

Shape: Square 60×60 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

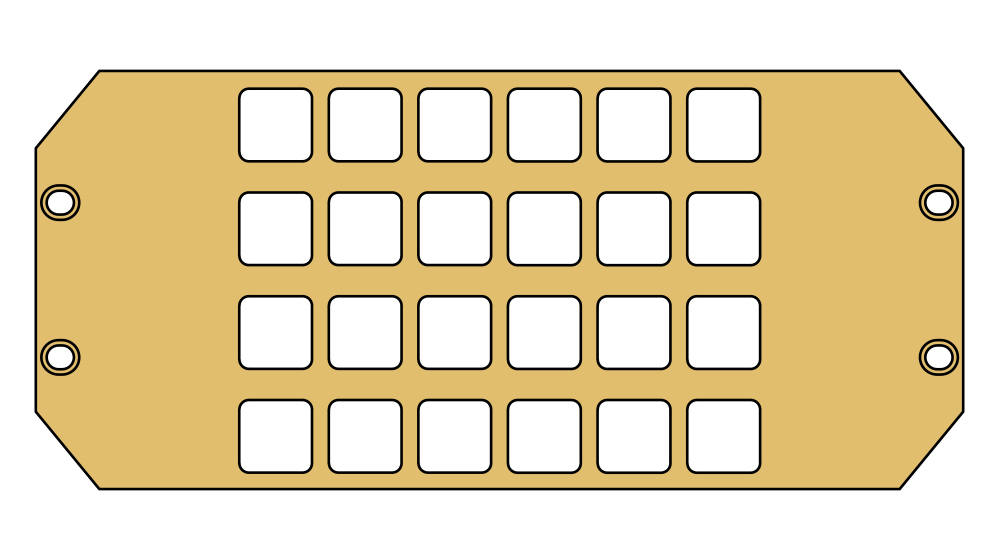

24/Q

Shape: Square 40×40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

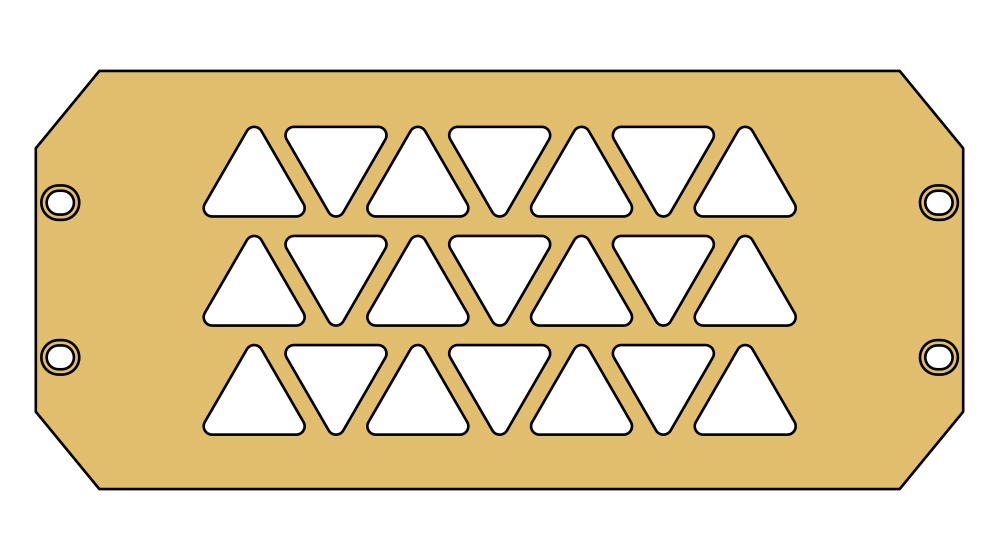

21/T

Shape: Triangular 56 mm per side

Pcs/cycle: 21

Capacity*: Up to 7.560 pcs/h

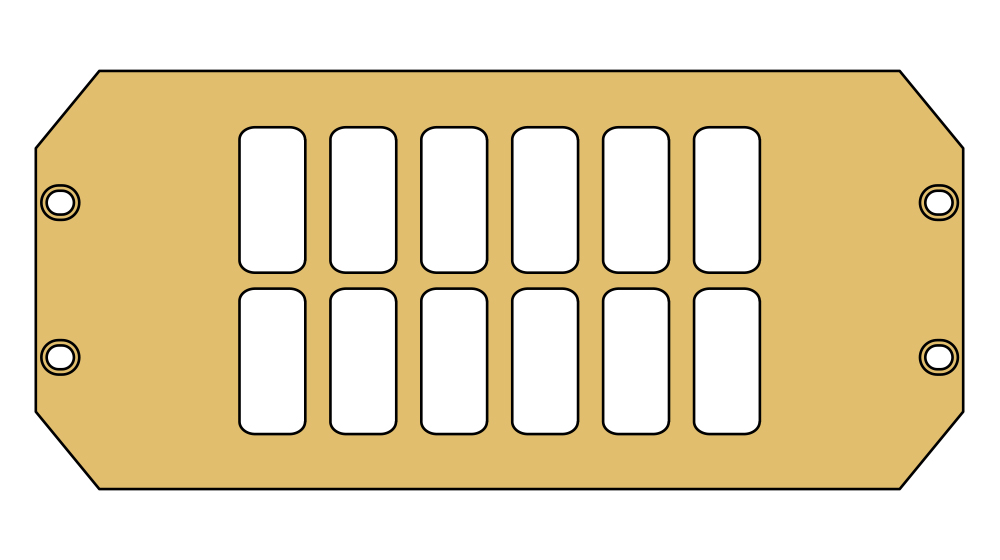

12/R

Shape: Rectangular 80 x 35 or 100 x 35 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

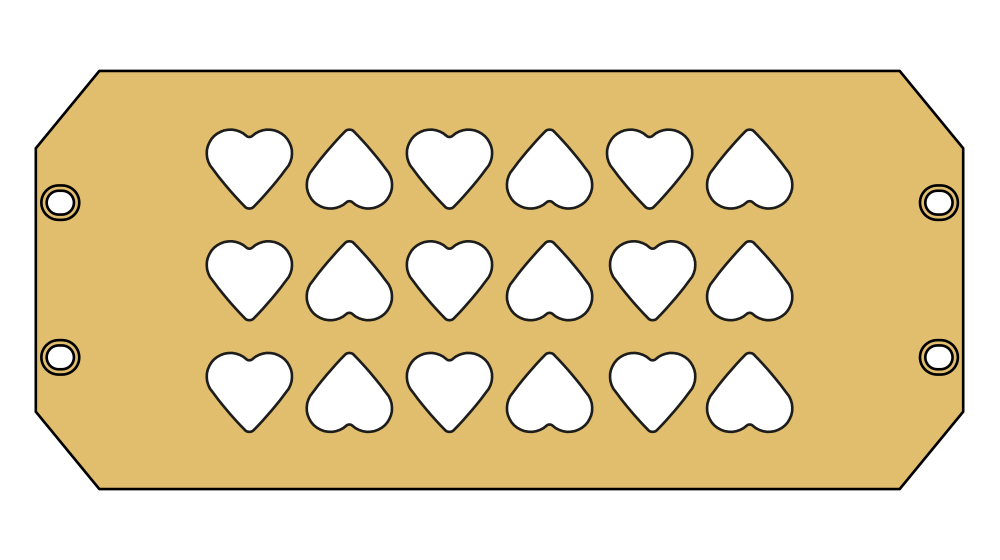

18/HR

Shape: Heart

Pcs/cycle: 18

Capacity*: Up to 6.480 pcs/h

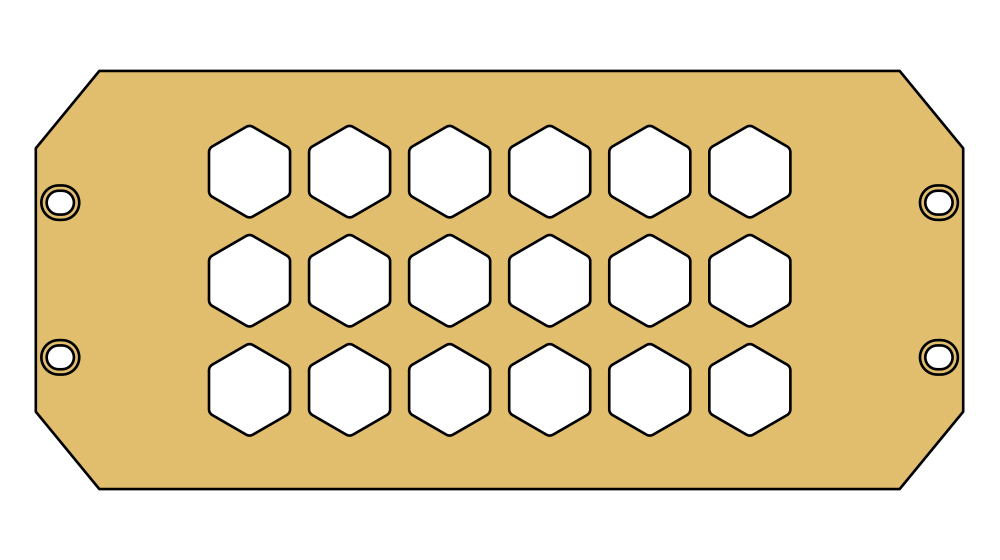

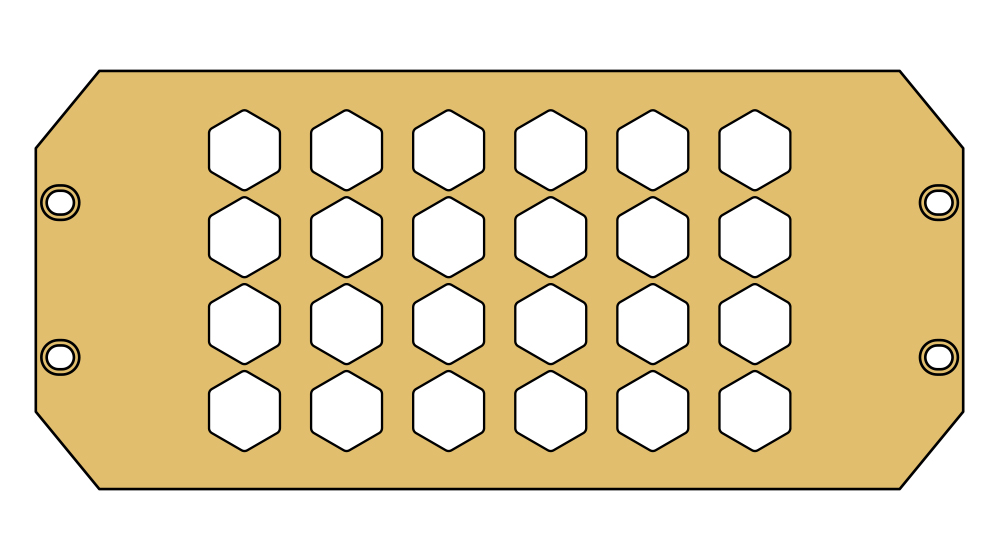

24/45HE

Shape: Hexagonal Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h