RE PIETRO SRL designs and delivers complete productions lines, from the processing machines to the packaging line, and offers an efficient after-sale service.

Popping Machine RP-EVO

NEW POPPING MACHINE RP-EVO: the r(EVO)lution is flexible.

With the NEW Popping Machine RP-EVO, the production of puffed cereal cakes or NO-fried snacks with the same machine becomes reality!

Choose the shape, assemble the appropriate mould, select the proper PLC program (for cakes or snacks) and that’s all. Because no Popping Machine is as flexible as the new RP-EVO.

Snacks and puffed cakes with one machine

The market demands healthy and low-fat products and the new RP-EVO, flexibly, responds.

Create your favorite recipe and let yourself be surprised: rice, corn, cereals, legumes and micropellets, combined in original and tasty mixes, become light and airy puffed cakes ideal for breakfast or as bread substitutes, but also crunchy and healthy popped snacks, of any shape and thickness. And all this is possible without changing machine. Because no Popping Machine is as flexible and easy to use as the new RP-EVO.

Certified Technology

Nickel coated steel frame, certified food contact material, stainless steel electric panel with a side rotating and swivelling touch screen control panel, set at eye’s level for easier use.

The Popping Machine RP-EVO series is equipped with a hydraulic unit for the movement of the mould capable of generating the necessary pressure for the expansion of the products and produce light, airy and tasty puffed cakes or crunchy popped snacks.

The volumetric dosing of the raw materials is carried out by means of a pneumatically moved feeding plate. The mould, beating heart of the machine, is made by hardened steel coated with titanium nitride, to guarantee solidity and a long-lasting life, and to prevent the sticking of the products on the same.

The heating of the moulds (upper and lower) is carried out using high density cartridge heathers and their temperatures are separately controlled. Each machine has its own PLC (Siemens S7-1200) and 7” control panel. From the HMI it is possible to set up each production phase, save the recipes and check any malfunctioning, thanks to its efficient diagnostic system.

The mould as well as all the parts of the machine getting in contact with food stuff are manufactured with suitable raw materials for the processing of the food stuff as required by the Regulation 1935/2004 –CE (MOCA COMPLIANCE).

Available models

Choose the shape of your snack.

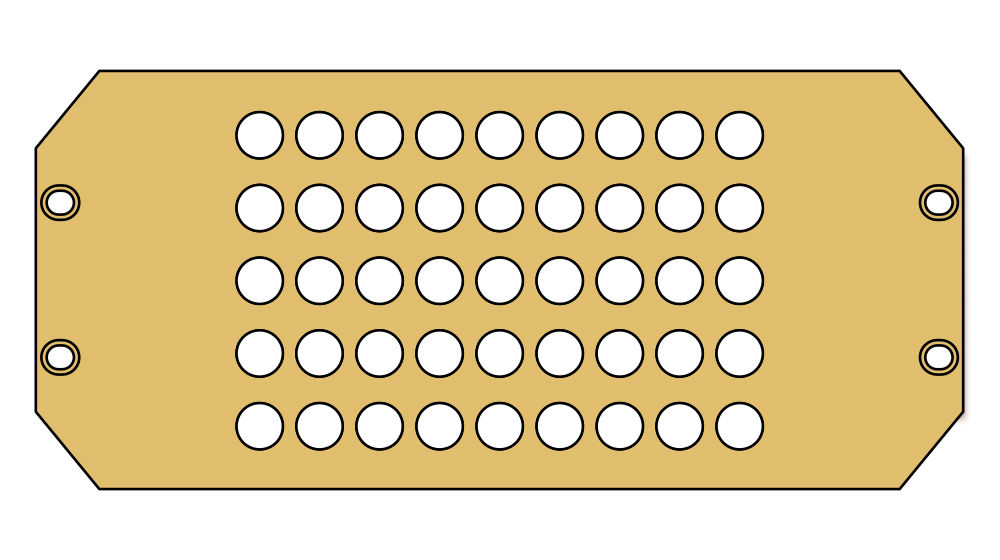

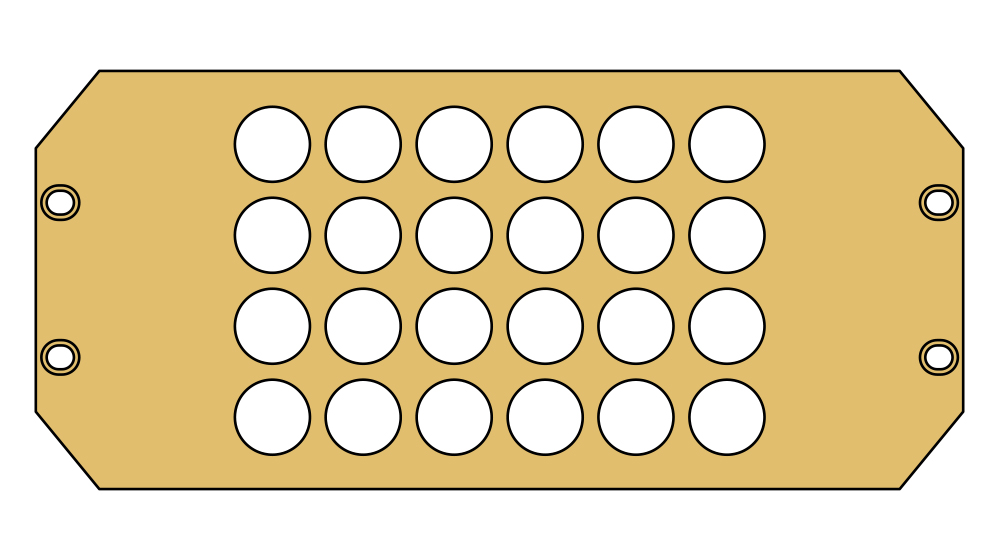

45/25C

Shape: Round Ø 25 mm

Pcs/cycle: 45

Capacity*: Up to 16.200 pcs/h

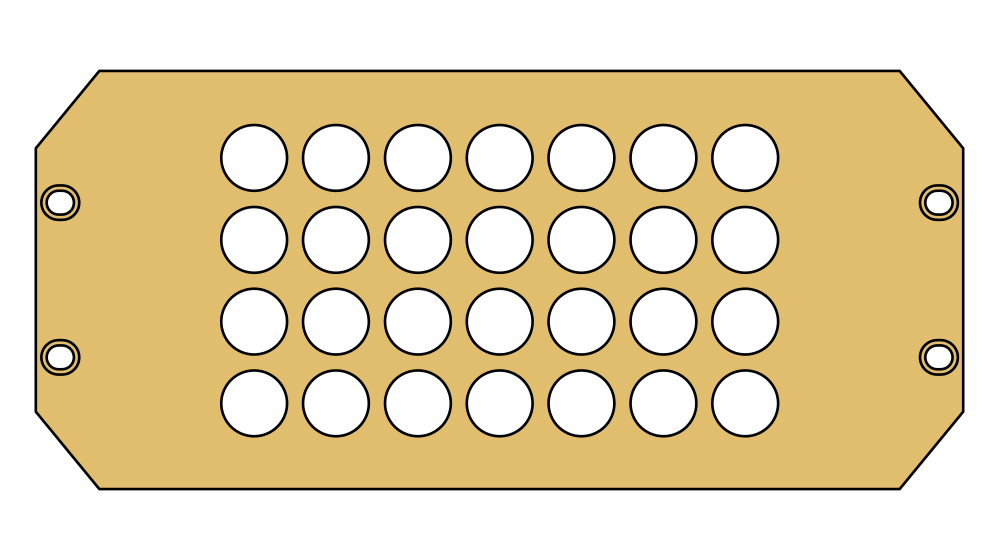

28/35C

Shape: Round Ø 35 mm

Pcs/cycle: 28

Capacity*: Up to 10.080 pcs/h

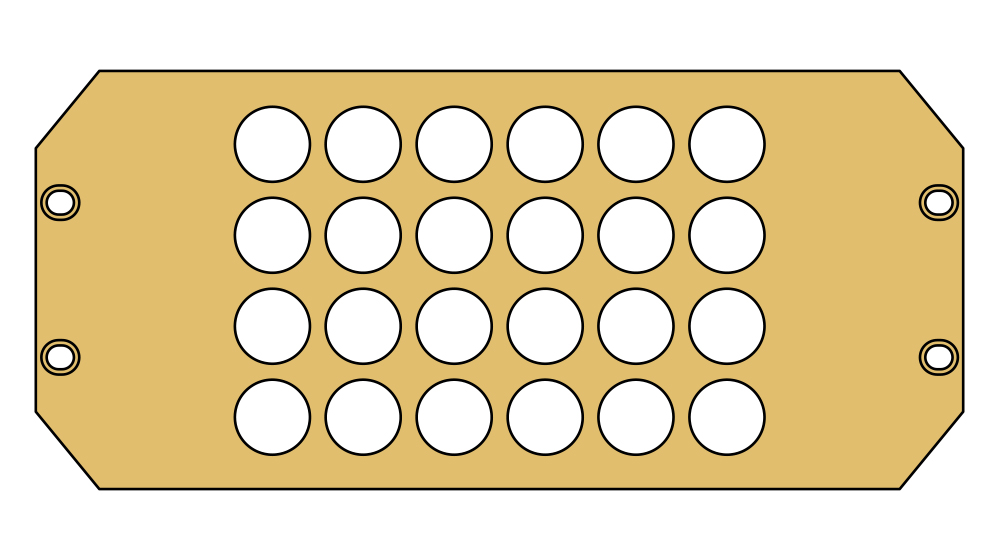

24/40C

Shape: Round Ø 40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

24/45C

Shape: Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

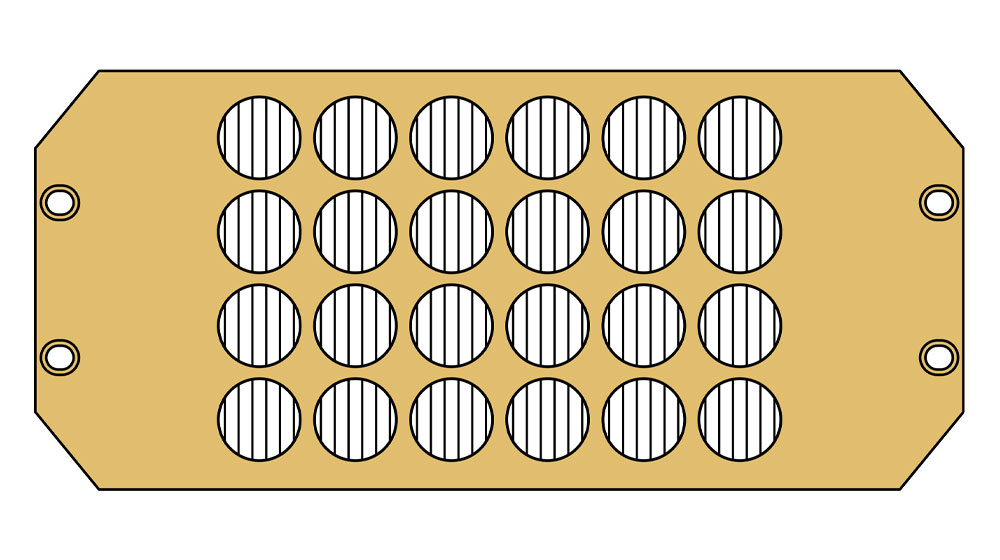

24/45CR

Shape: ridge Round Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

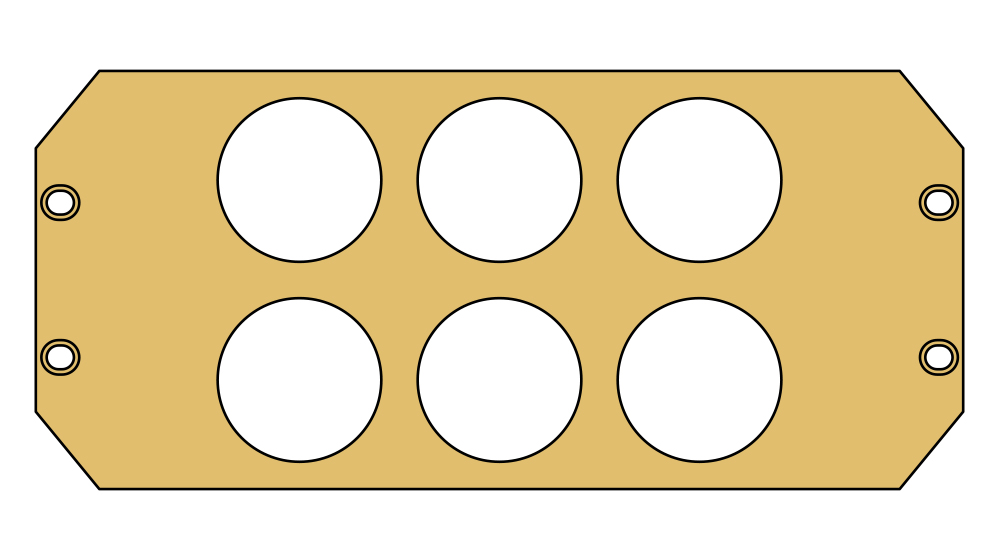

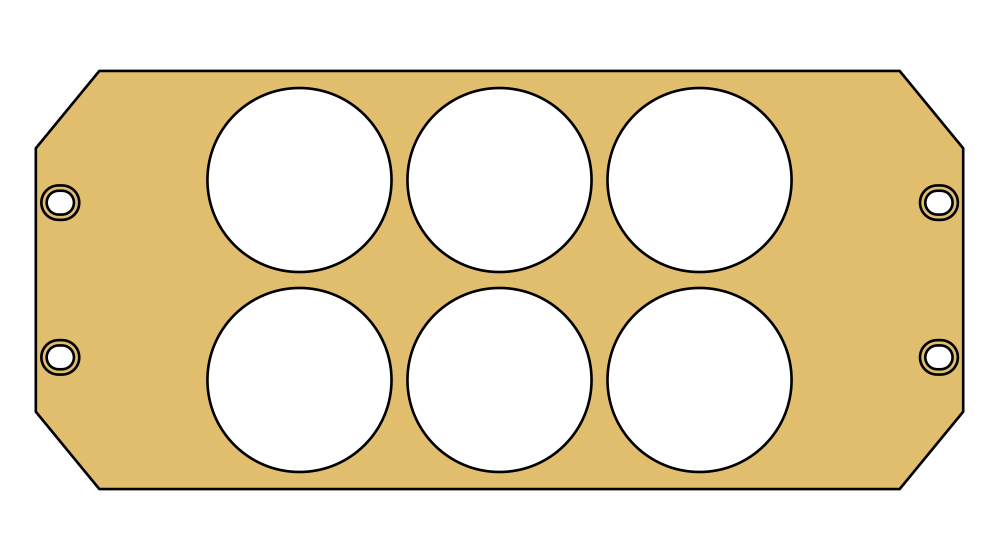

6/90C

Shape: Round Ø 90 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

6/100C

Shape: Round Ø 100 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

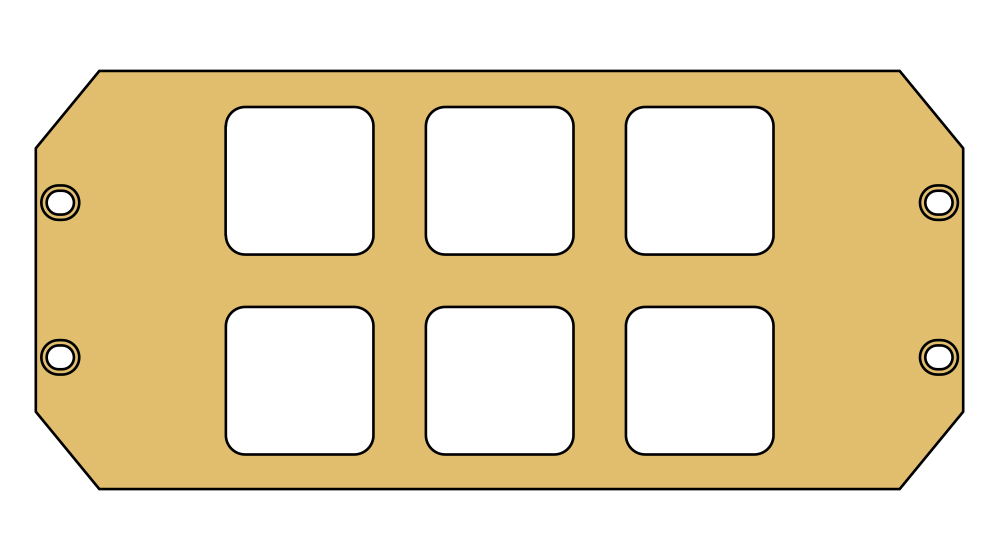

6/Q

Shape: Square 80×80 mm

Pcs/cycle: 6

Capacity*: Up to 2.160 pcs/h

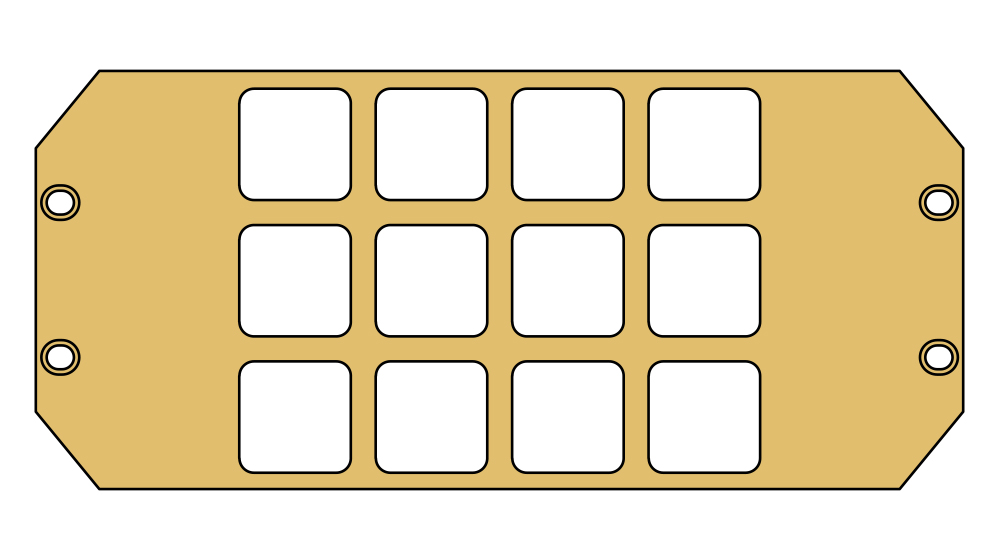

12/Q

Shape: Square 60×60 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

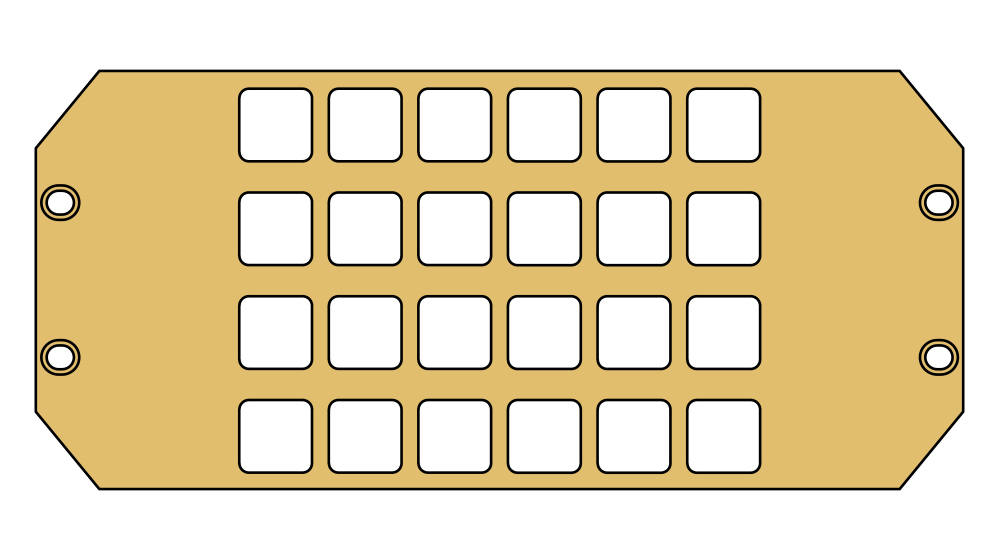

24/Q

Shape: Square 40×40 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h

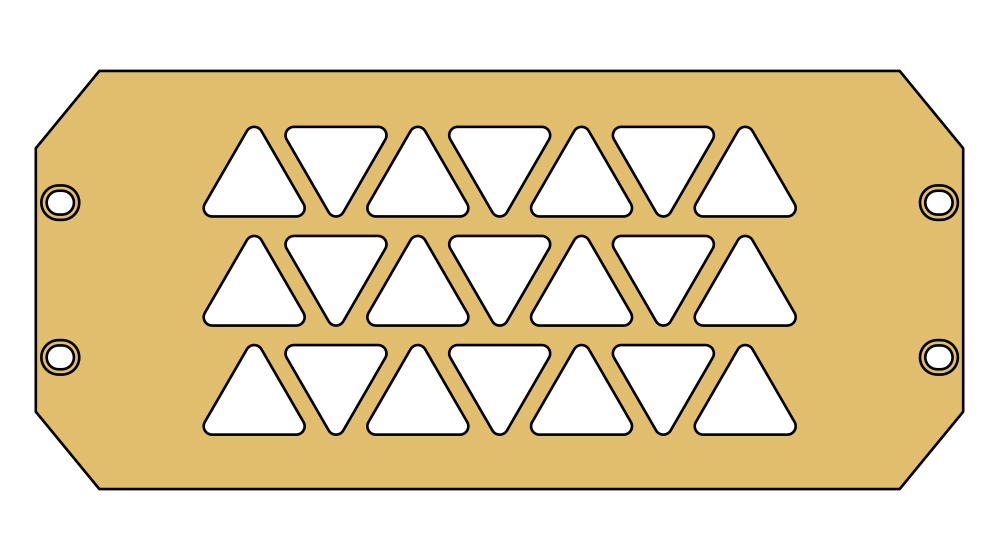

21/T

Shape: Triangular 56 mm per side

Pcs/cycle: 21

Capacity*: Up to 7.560 pcs/h

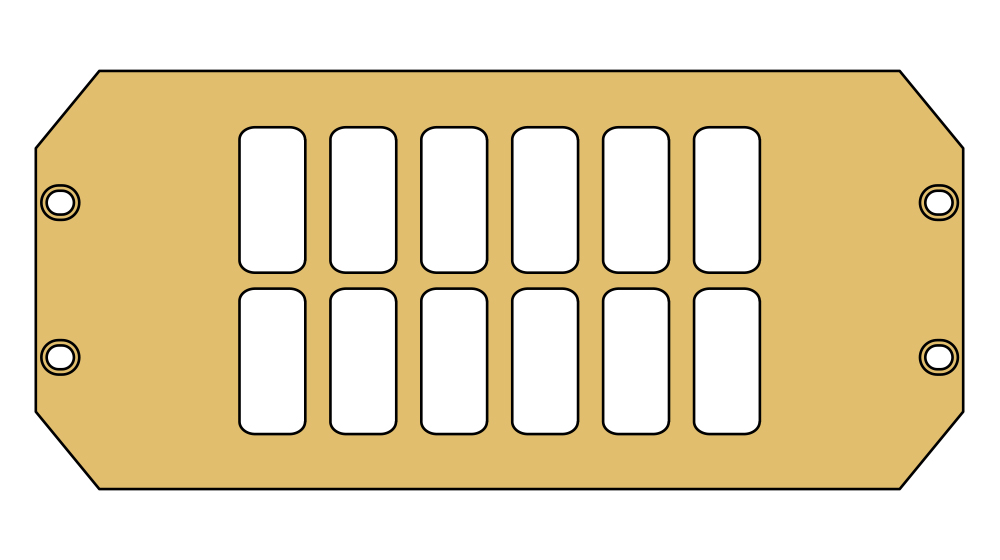

12/R

Shape: Rectangular 80 x 35 or 100 x 35 mm

Pcs/cycle: 12

Capacity*: Up to 4.320 pcs/h

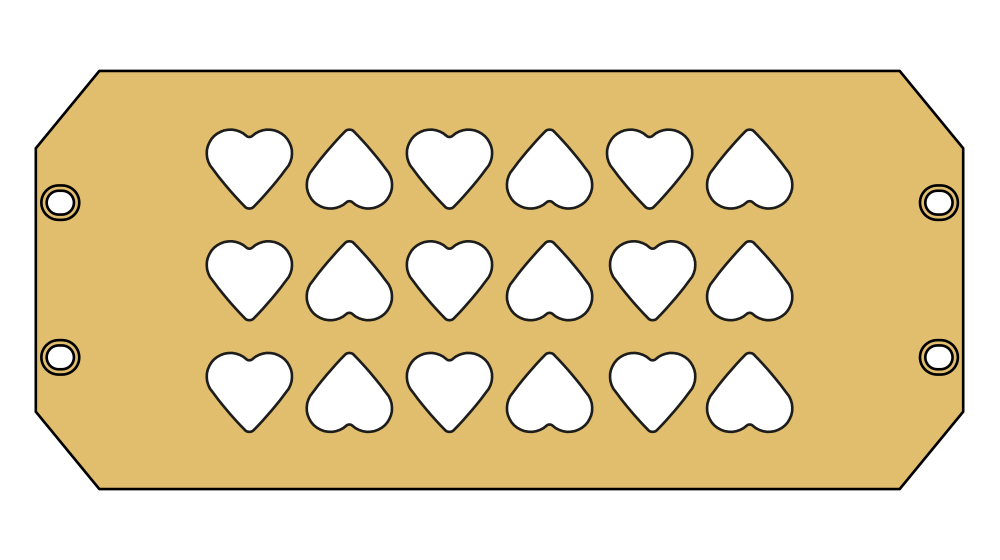

18/HR

Shape: Heart

Pcs/cycle: 18

Capacity*: Up to 6.480 pcs/h

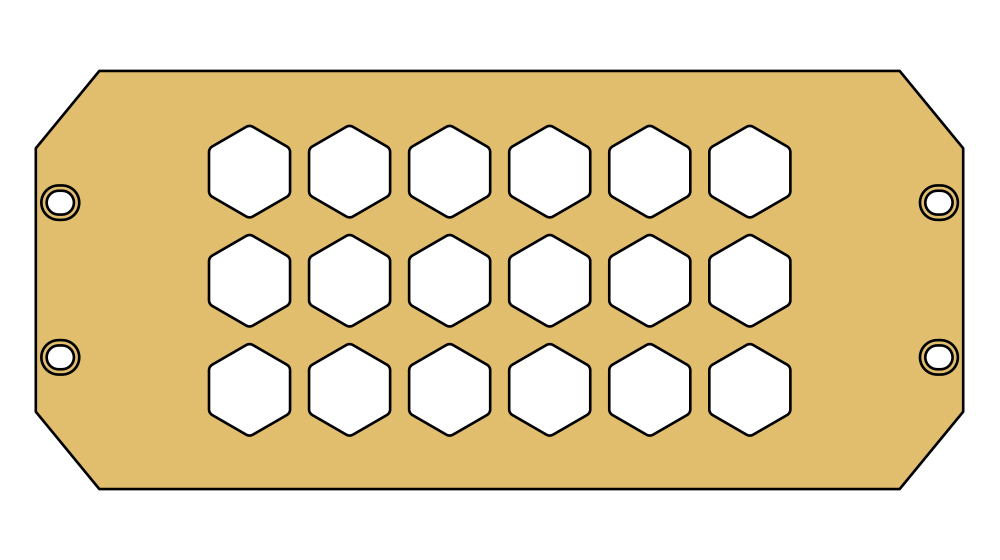

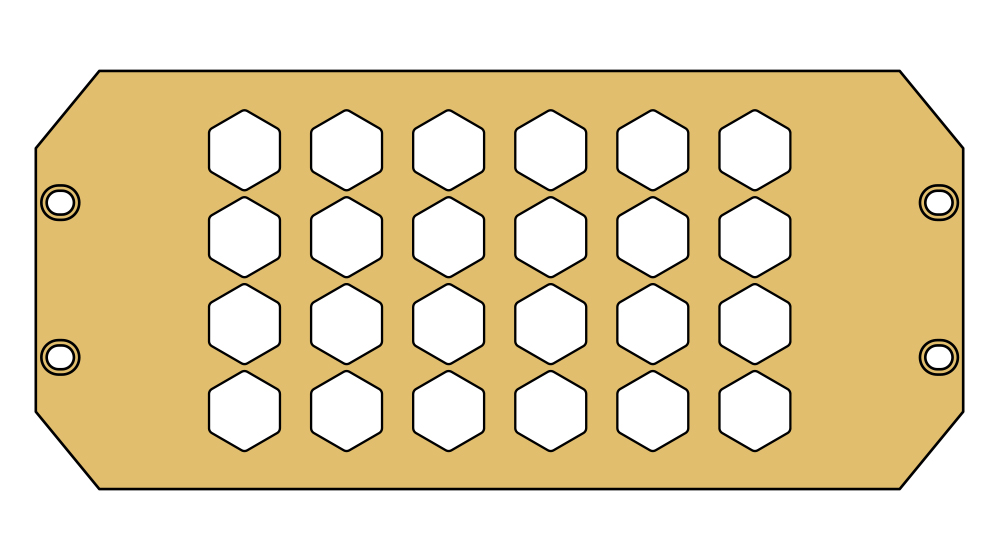

24/45HE

Shape: Hexagonal Ø 45 mm

Pcs/cycle: 24

Capacity*: Up to 8.640 pcs/h